Real-Time Measurement using the ILA1-X000-EX laser Gas Analyzer

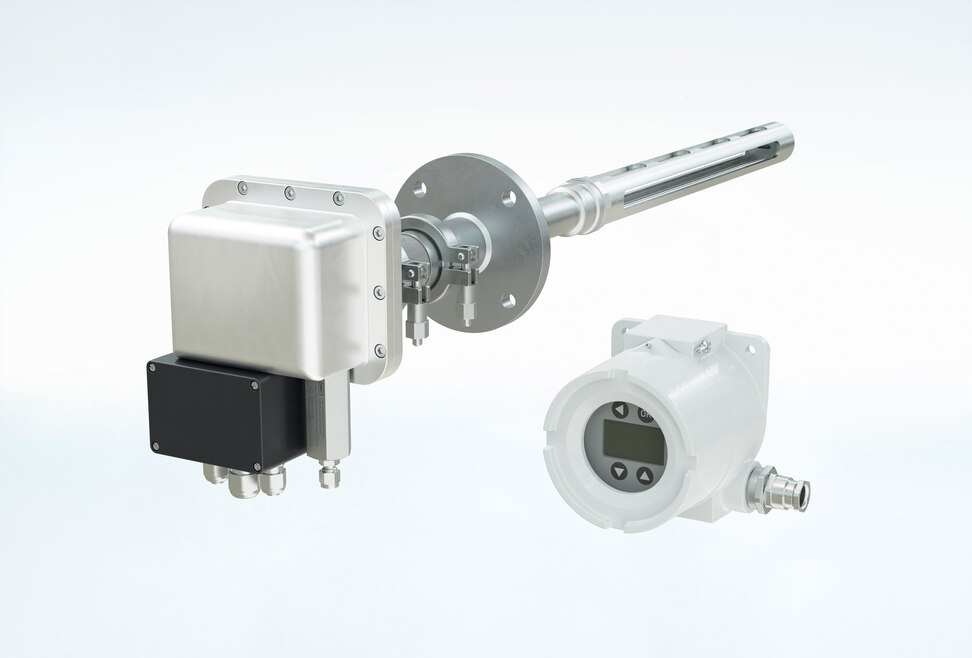

The ILA1-X000-EX In-situ Laser Analyzer measures oxygen (O2) or sulfur dioxide (SO2) in real time and is designed for industrial applications as well as for use in potentially explosive atmospheres. The analyzer requires just a single process flange for operation.

The ILA1-X000-EX In-situ Laser Analyzer is an in-house M&C development and consists of a sensor head with a transmitter and a receiver as well as a probe tube with mounting flange and reflector. A separate HMI unit is available as an option.

Due to its measurement method, the ILA1 Laser Analyzer is very reliable and designed for short response times. In addition, the robust design enables its use under demanding process conditions in a variety of industrial and chemical processes. Gas sampling and conditioning are not required for the measurement. It therefore helps to minimize downtimes and increase process stability at low operating costs.

In summary, the ILA1-X000-EX is an optimal analyzer for real-time measurements with very high precision, maximum reliability and minimum maintenance.

You have questions about the ILA1 Laser Analyzer?

Marco Meer

Product Manager Laser Analyzer

Phone : +49 2102 935-134

Multigas Analyzer GenTwo V2.4

Our multigas analyzers of the GenTwo series come in a new, revised system design in version V2.4. In the future, the analyzers can be supplied either in the established 19" rack-mount housing or alternatively in a robust wall-mount enclosure with protection rating IP54. In addition, we offer either Viton® or PTFE tubing or stainless steel piping for the gas paths.

A variety of different sensor types can be integrated into our GenTwo V2.4 to meet a wide range of requirements for measuring tasks, e.g. in the fields of combustion control, process optimization, inertization monitoring or environmental protection.

You have questions about the GenTwo Multigas Analyzer?

Andreas Gatzemann

Product Manager Analyzers

Phone : +49 38209 87 74 26

Alternative to the standard procedure for mercury measurement

A new product in M&C's portfolio is a Sorbent Trap device for mercury measurement. The DIN CEN/TS 17286 standard, which was adopted at European level in 2019, provides for the use of sorbent traps as a reference method for mercury measurement.

The Sorbent Trap system is a device for discontinuous measuring. It actively extracts flue gas from the process, which is then directed through the sorbent traps. As a result, an arithmetic mean value is obtained over a period from 0.5 to 336 hours. After the collection period has elapsed, the traps are removed from the probe and sealed. The analysis is performed in the laboratory. New unloaded sorbent traps are used for further measurements.

Further product advantages are:

- No wet chemical operating materials

- Limits of detection: 2 µg/Nm3 up to 0.01 µg/Nm3

Reduction of Sulphur Emissions for the Maritime Industry from 2020

As of January 1, 2020, a reduction in sulphur emissions for all international ships outside the ECAs from 3.5 % to 0.5 % came into force.

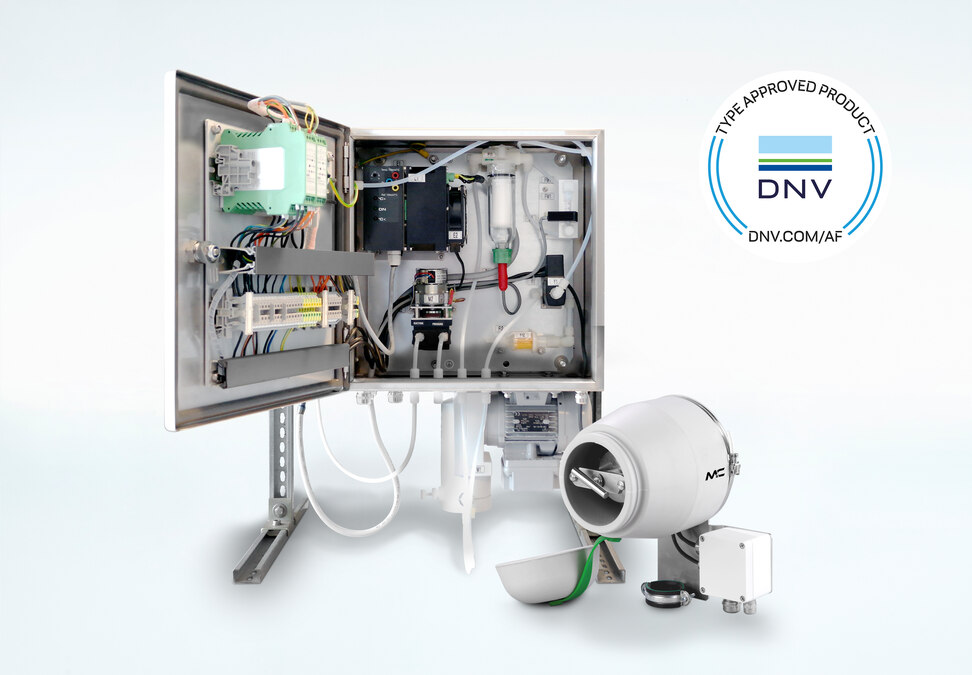

The M&C gas conditioning system SSM0-5 and the sample probe SP180H-MA have been tested by independent certifiers (Germanischer Lloyd). They are designed to help the maritime industry, oil refineries and commodity traders comply with legal requirements by performing the gas analysis process using the analyzer provided by the customer.

SP180-H – now available as Ex1

SP 180-H EX T2/T3/T4 Gas sampling probe available with Ex1-certification according to ATEX/IECEx: Ex II 2G bc mb IIC T2 Gb EXAM BVS 18 ATEX E 043. IECEx BVS 18.0034

The new, electrically heated gas sampling probe SP180-H can be used for a continuous gas sampling. Due the compact design, little space is required for mounting.

The gas sampling probe SP180-H provides:

- Gas sampling from dusty processes

- Low volume, quick response time

- Simple mounting and service

- Self-regulating electrical heating

- Low-temperature alarm contact

- Outside mounting possible due to new insulated cover

- Connection for test gas according to EN 14181 which enables calibration through the filter is included as standard

- Options for mounting sample tubes

High-Performance "Plug and Play" Peltier Cooler Series ECP-C

The successor series of our ECP coolers shows a significant increase in performance compared to the previous series. Due to the possible absolute value and differential temperature control, the devices can be integrated into a variety of applications. They fulfil all requirements to ensure user-friendly operation on account of “Plug and Play" modules, a broadband power supply unit (85 V to 240 V), the rapid cooling down to operating temperature (adjustable between 2 and 15 °C) and a new intuitive control panel. Furthermore, the new Peltier cooler series ECP‑C offers the possibility to mount up to two peristaltic pumps and have them supplied by the device.

Further product advantages:

- Adjustable alarm limits

- Configurable liquid alarm evaluation for sensors with and without cable break detection

- Configurable mA output

- Can be used at ambient temperatures of up to 50 °C (without extra charge)

New EN 15267-4:2017 Air Quality Standard

The revised standard EN 15267-4:2017 entails a number of new requirements. The higher requirements include e.g. a higher protection class – IP42, a gas temperature monitored by signal control and a temperature display that is visible from the outside.

In order to meet these requirements, the portable M&C gas conditioning system PSS5 has been adjusted accordingly and now complies with all required specifications under the name of PSS5C. In addition, it is easier to use since the case only needs to be opened for maintenance purposes.

Further product advantages:

- Impact-resistant material

- 3in1 case with integrated trolley and shoulder strap

- Tool-free mounting of the sample gas line to the PSP4000 possible

- New, high-performance coolers installed (optionally 4 to 20 mA)